Batch production is often used for making group orders, and not used for mass manufacturing. Because batch manufacturing involves small batches, it’s good for quality control. For example, if there is a mistake in the process, it can be fastened with out as a lot loss compared to mass production. This can even lower your expenses by taking much less risk for newer plans and products and so on. As a end result, this permits batch manufacturing to be changed or modified depending on company wants. Overall, when a company is trying to find options on tips on how to manufacture uniform products that are made on-demand, batch production is a great solution.

This example exhibits the way to mannequin and optimize the use of shared assets in a system, to identify useful resource deficiencies and enhance capacity planning. The example is based on a batch manufacturing process, where production orders are processed only based on the availability of batch reactors. In the example, SimEvents® entities symbolize each the manufacturing orders of the manufacturing process, and the batch reactors which might be required to course of them. Later within the example, we’ll find the optimum resource capacities of the system by making use of the Genetic Algorithm solver of MATLAB Global Optimization Toolbox. Producing merchandise in batches is inefficient because of the downtime related to the method. Manufacturers usually need to shut down machines and reconfigure them for each new batch they produce.

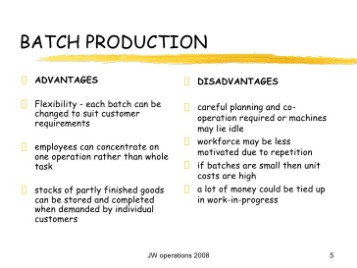

Using the batch process on a selected set of machines, they produce the 500 giant pillowcases their client needs. Each process you implement can have dramatic ripple effects on your business. This is why you always need to analyze the details and know all of the nitty-gritty particulars behind what’s manufacturing. The disadvantages to batch manufacturing which has been highlighted here could not apply to the same extent to your small business. You should think about if the advantages similar to further customization and saved time on establishing are price themanufacturing costof the strategy. Clearly then, there are downsides to batch manufacturing which should be accounted for when choosing which manufacturing process to implement.

Benefits & Disadvantages Of Batch Manufacturing

So, what’s the most advantageous a part of batch production in accordance with you? With the assistance of batch manufacturing, you will be able to make use of one manufacturing system for making seasonal items with utmost efficiency and optimized productiveness. Make certain that you try it out as soon as to have the most effective results for the business that you’ve. Here we now have another one of the advantages which could come along with the amazing batch manufacturing of the gadgets. We all know that a single machine will be used to fabricate the merchandise in a single step.

- The early mechanics of processing a batch involved feeding a pc a stack of punched cards that held instructions, or instructions, for the computer to comply with.

- Reconfiguring the production system to produce one thing different leads to downtime.

- Easily observe product movement and storage down to the bin or pallet throughout staging areas, a number of warehouses, vans, and even ships prior to import.

While some tasks are done instantly, others are performed in real-time. If there are any problems with the process, the system notifies the appropriate personnel by way of exception-primarily based administration alerts. This saves managers time for his or her daily duties and other urgent duties without having to oversee the batch processing system. A defining characteristic of batch processing is a scarcity of human intervention, with few, if any, guide processes to kick it off.

Small Batch Manufacturing: Lowering Costs, Rising Profit

The group stays together because it passes through each stage of production until all processes are full. For example, clothes may be produced in batches of different sizes and hues. The process, subsequently, includes a delay between batches while equipment is changed or recalibrated; this is called downtime. When it involves the clothing gadgets, these may be produced very simply within the batches of the colors as well as the sizes too. The batch production process, in consequence, includes a form of delay whereas all the tools is accordingly recalibrated, and this delay is called downtime. The products which are manufactured within the strategy of batch manufacturing are then saved as batches or groups.

Batch processing helps in dealing with tasks like payroll, end-of-month reconciliation, or settling trades in a single day. The process involves 4 steps and the whole batch is moved from step to step together. When the batch of bread is finished, workstations are reconfigured for a batch of english muffins. For profitable software of pc colourant formulations, nicely-educated and skilled personnel are required. At the start, considerable thought must be given to integration of the system into the working environment of the plant. The limitations of production rely to a large extent on particular issues in the individual case; these can solely be overcome via individual effort.

Also, the workers are all specialised, and they don’t have to be multi-expert to qualify for batch manufacturing as a result of the gear does most of the work. The merchandise that are produced on this course of are very less personal, and these usually are not actually within the particular person form according to the requirements of the purchasers. The entire focus of the method is to be sure that the merchandise which are produced have a very top quality, and these merchandise can be afforded by the people who find themselves prospects. A specific batch which has been completed might be then moved from one production stage to the opposite one till the entire process of manufacturing is completed as an entire. When there is a manufacturing in the type of batches, then there shall be much less time required for the changing of the components and the motion of the machines. Also, there are some other actions which will require lesser time too.

The Benefits Of Combination Planning

Recipes related to every load of uncooked materials could be processed into product. A process is considered to be a batch course of if the method consists of a sequence of a number of steps that should be performed in a defined order. Batch process manufacturing facility is less complicated to scale up depending on market demand and requirements. Batch manufacturing plants are comparatively extra strong than a steady plant. Production of a narrow specification product, i.e., greater and constant product high quality.