Batch production is often used for making group orders, and never used for mass production. Because batch production entails small batches, it is good for quality control. For instance, if there’s a mistake in the process, it can be fastened without as a lot loss in comparison with mass manufacturing. This can even get monetary savings by taking less risk for newer plans and products and so forth. As a end result, this enables batch manufacturing to be changed or modified relying on company wants. Overall, when an organization is searching for solutions on tips on how to manufacture uniform products that are made on-demand, batch manufacturing is a great answer.

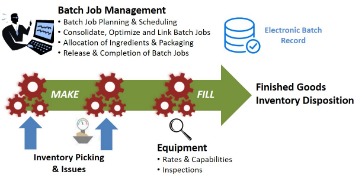

Proving to oneself as well as the regulatory businesses (e.g. US Food & Drug Administration ) that a drug was manufactured appropriately is one driving factor for pharmaceutical companies. The drive for digital batch information has produced the FDA 21 CFR Part eleven Regulation on digital information and electronic signatures that permits batch history to be recorded electronically. This helps to switch older exhausting copy information and signatures, which have been previously the only FDA-acceptable batch information. Optimizing the plant is another necessary reason for capturing batch history.

Batch manufacturing is the place the manufacturing process is split into a variety of totally different operations; every of which is carried out on the entire batch before it is moved on and one other batch acquired. The batch is moved on from one stage of manufacturing to the following until all the manufacturing processes are accomplished. Batch production involves the manufacture of a bunch of similar items and is generally used when the demand for the product is comparatively fixed. One of an important issues that the producers should do is present seasonal products in order that the purchasers can use them.

Instance Of Batch Production

They additionally should be retest machines to make sure their output is on track for the merchandise being made. The downtime between batch runs can be prolonged if the production course of is difficult or includes several machines. In any batch production course of, it is very important have an correct and complete batch historical past for a lot of causes.

- The early mechanics of processing a batch concerned feeding a computer a stack of punched playing cards that held instructions, or directions, for the computer to follow.

- Reproduction of supplies found on this web site, in any form, without explicit permission is prohibited.

- Reconfiguring the production system to produce something different ends in downtime.

- Easily track product movement and storage right down to the bin or pallet throughout staging areas, a number of warehouses, vans, and even ships prior to import.

While some tasks are carried out immediately, others are carried out in actual-time. If there are any problems with the process, the system notifies the appropriate personnel through exception-based mostly administration alerts. This saves managers time for their daily duties and other pressing tasks with out having to supervise the batch processing system. A defining characteristic of batch processing is a lack of human intervention, with few, if any, guide processes to kick it off.

Small Batch Production: Decreasing Costs, Increasing Revenue

Batch production is a technique of manufacturing where the merchandise are made as specified teams or quantities, inside a time-frame. A batch can undergo a collection of steps in a large manufacturing process to make the final desired product. Batch production is used for many kinds of manufacturing that may need smaller amounts of production at a time to ensure particular high quality standards or changes in the process. This is against giant mass manufacturing or steady manufacturing strategies where the product or process doesn’t need to be checked or changed as incessantly or periodically. Batch manufacturing is a manufacturing methodology by which merchandise are manufactured in groups referred to as batches quite than in a steady style. In batch production, a group or set or batch of merchandise are made, and the same equipment is used to make the subsequent batch of products.

Batch processing helps in handling tasks like payroll, end-of-month reconciliation, or settling trades overnight. The process includes 4 steps and the entire batch is moved from step to step collectively. When the batch of bread is finished, workstations are reconfigured for a batch of english muffins. For successful utility of laptop colourant formulations, well-educated and trained personnel are required. At the start, appreciable thought must be given to integration of the system into the working environment of the plant. The limitations of production depend to a big extent on specific problems within the particular person case; these can only be overcome via individual effort.

Also, the employees are all specialized, and so they don’t have to be multi-skilled to qualify for batch production as a result of the equipment does many of the work. The products which are produced on this process are very much less personal, and these aren’t really in the particular person form according to the requirements of the shoppers. The complete focus of the process is to be sure that the merchandise that are produced have a really high quality, and these products may also be afforded by the people who are prospects. A explicit batch which has been accomplished might be then moved from one production stage to the other one until the entire course of of producing is completed as a complete. When there’s a production in the type of batches, then there shall be much less time required for the changing of the elements and the motion of the machines. Also, there are some other actions which would require lesser time too.

At the top stage of the mannequin, the Entity Generators simulate the era and backlog of manufacturing orders by producing entities that characterize production orders. When a brand new entity is generated, the Obtain Reactor block requests a batch reactor to course of the order. The Data Analysis subsystem analyzes knowledge related to completion of production orders. It can be tough to manage waste and financial losses in meeting line manufacturing. Big manufacturing lines often include expensive assembly machines that are only economical for producers to use at high outputs. However, massive production runs enhance the chances for manufacturing errors that produce faulty products a producer can’t sell.